Business Process Reengineering is a relatively new term, which became popular in the late 1990s. It was coined by Michal Hammer in his article for Harvard Business Review.

Hamer argued that instead of trying to improve and automate existing processes, businesses should look for ways to completely redesign them to achieve improved efficiency.

Business process reengineering is a radical and uncertain process that involves completely abandoning existing operations in search of a better way to do things.

If done right, BPR can bring game-changing results to your company’s overall efficiency. And while the potential benefits can be rewarding, the risks of failure are very high.

We’ve seen many companies attempt and fail at executing a proper BPR strategy. That’s why we decided to create this complete guide to Business Process Reengineering.

Below, we’ll cover:

- What is business process reengineering (BPR)

- Common BPR pitfalls

- Tips that will help you implement BPR effectively

- 5 business process reengineering steps you need to follow for every initiative

- 5+ business process reengineering examples

- Where BPR falls into the process management world, and how is it different from BPI, BPM, and other terms

Let’s get started!

What is Business Process Reengineering (BPR)?

Business Process Reengineering is an act of redesigning company processes to achieve higher efficiency, lower costs, and/or higher quality

As Hammer put it, sometimes companies spend too much time trying to automate and improve inefficient processes. Instead, they could try to revolutionize the existing processes by creating something entirely new.

If your business processes are utilizing outdated technology or have redundant steps in core processes, then BPR can help your company become more efficient. Otherwise, you might end up trying to reinvent the wheel by redesigning something that works.

In simple terms, BPR goes like this:

- You create a process map – a visual representation of how different processes within your organization work (as-is state).

- Once you analyze the map and identify areas for potential improvement, you can brainstorm different ways to redesign inefficient processes.

- Afterward, you should create a future process map (to-be state) and come up with a thorough implementation plan

- Execute the plan and measure key performance indicators consistently (We will talk about that later)

Of course, there’s a lot more to it, but we’ll get into the nits and grits a bit down the line.

A successful business process reengineering can turn an average company into an industry leader. A good example would be Ford company and how they redesigned their production processes, substituting manual work with an assembly line.

Before 1913, Ford’s workers produced their cars manually and the production was not streamlined. Once the company introduced new machinery and redesigned the production process into an assembly line, Ford decreased the time it took to build their cars from over 12 hours to 2.5 hours.

BPR pitfalls: Lack of Innovative Thinking

A lot of companies fail when they ignore the need for change and innovation. By not executing BPR when it was called for, even the most successful companies can plummet to bankruptcy. An excellent example of such a company is Kodak.

By 1976, Kodak was a world-leader in colored film-production, which comprised the biggest revenue stream for the company. This factor made Kodak rely on film as their key product for over 20 years, which limited the innovation.

As a result, Kodak revenues declined once more cost-effective Fujifilm entered the American market and digital photography emerged. Worst of all, Steven Sasson, a man who created the first digital camera, worked for Kodak. His invention was ignored by Kodak management. History proved them wrong. In 2012, Kodak filed for bankruptcy.

6 Practical Business Process Reengineering Steps

Now as you generally understand the concept of business process reengineering, it is time to introduce you to the EXACT steps that you need to follow to implement BPR successfully in your company.

Step 1: Measure Existing Processes & Spot Inefficiencies

Before you attempt to build a new engine to fuel your company’s operations, you need to understand whether it needs a new engine in the first place. The worst thing you can do is trying to change something that works.

You can identify inefficiencies by looking at the process and measuring its’ performance. A good way to do it would be looking at the industry averages, as well as the performance of industry leaders in similar processes.

For example, if you are a tire manufacturer and it takes you 2 hours to produce a set of tires, while Goodyear manages to do it in 1 hour, it is a sign that your production process might be inefficient. Business Process Reengineering can help you fix that problem.

You can usually find information about the industry in different articles and scientific publications, as well as industry reports. If you are trying to analyze financial data, you can find a lot of data free of charge on Yahoo Finance.

Once you have measured the performance of your processes and compared them with the performance of other organizations, it will be easier for you to make an educated guess on whether you need business process reengineering or not.

Step 2: Communicate the Need for Change

It is only natural for people to resist change. Your workers might be worried that with a redesigned process, their work will become obsolete. However, this does not necessarily have to be the case: a successful BPR implementation brings more benefits than detriments to the company.

For instance, when processes within the companies get automated by either a robot or software, employees end up doing more meaningful tasks.

For instance, a person that was responsible for packing boxes at your production plant manually (and making about 500 packages daily), can end up handling the machinery that produces 5000 pieces daily.

BPR does a great job of eliminating meaningless and repetitive tasks that kill employees’ motivation and mess up your company’s productivity.

This leads to fewer expenses for the company and higher revenues, which is usually a good thing for people within the company (e.g. with higher output, you can pay your employees more and provide them with more interesting tasks)

Therefore, as a successful leader, you need to communicate the benefits that the change will bring to the organization as a whole and how it will benefit your employees personally. If you establish the connection between corporate benefit and personal gain of your employees, then change will be feared less.

For that to happen, you need to involve your employees in the change process and get their acceptance. There’s no one way to do it but there are positive change management practices that can help you execute this process:

- Communicate the vision clearly

If you want people to follow you, you have to make it very clear why change is good for the organization (and for them). As a leader, it is your responsibility to create a concise vision and communicate it through the company.

2. Acknowledge the importance of every employee

You have to understand the roles of your employees and assign clear tasks to them in the process of implementing change. This will improve the flow of communication and make the implementation process faster.

3. Learn to listen

No matter how good you think your strategy is, it is important to listen to your employees’ opinions. This will enable you to look at your strategy from different perspectives and make your employees feel more involved in the process. This is crucial to get their acceptance.

4. Prepare to modify the change

Based on the feedback that you will get from your employees, you might want to change certain aspects of your strategy to increase the chance of employee buy-in. Moreover, with more suggestions, you will get a better perspective on how to reengineer the process better.

Step 3: Assemble a Team of Experts

Needless to say, you cannot implement business process reengineering without a team.

While the upcoming business process reengineering should be communicated company-wide, 3 key groups of experts will help you with BPR implementation

- Senior Management

Senior managers are leaders when it comes to change management. They are going to make sure that your change strategy is being implemented in the respective department. They are going to track the implementation of the new process and report it to you whenever is needed.

They are also responsible for planning and directing the work of other individuals within the company.

Senior managers assemble task forces and approve changes whenever is needed (with no need for further approval).

Therefore, they should understand the company processes well and know the capabilities of their workers. These two factors will enable effective management and task assignment.

2. Operations Manager

Operations managers lead specific processes and teams during business process reengineering. For instance, in the manufacturing process, the operations manager will be the team leader at a specific site.

Therefore, an operations manager is the head of the team, who will lead the implementation process in a specific department or project related to your BPR strategy.

Depending on the business, they can be different people. They could be software engineers working to implement a more efficient POS system or HR managers in a sales agency. Two key characteristics that they share are strong technical knowledge and the ability to coordinate people.

Therefore, they are essential assets for your company insofar they figure out how to redesign the process to make it more efficient.

3. Technical Experts

Last but not least, technical experts are the people who are going to do the hard work of redesigning the process itself.

They can be just about anyone with the relevant technical experience, including software developers, engineers, etc.

For example, in the manufacturing industry, it could be the engineers who design new machines that can replace human labor in the packing department to increase production efficiency.

Step 4: Pick Relevant KPIs and Monitor Constantly

Key performance indicators measure the success of your business process reengineering initiative according to specific predefined metrics.

They help you better understand if your business process reengineering is going in the right direction by comparing the key statistics of old versus reengineered processes.

For example, let’s say you’re redesigning your sales team training process.

You’d want to check if the average number of sales per representative has increased compared to the old training system.

Depending on the type of project and department, you’d pick a different KPI. Here are some of the most common ones by department:

Sales Department KPIs:

- Average Deal Size

- Closed Deals per representative

- Customer Loyalty

- Number of deals per partner

- Sales Cycle Time

Marketing Department KPIs:

- Ad Click-through Ratio

- Cost per Lead

- Effective Reach

- Response Rate

- Cost of Customer Acquisition

Financial Department KPIs:

- Accounting Costs

- Cost per Transaction

- Time to Process Payroll

- Cost of Goods Sold

- EBIT

When you are monitoring your KPIs, you generally want to do the following:

- Measure the process inputs (e.g. how much resources does it take you to produce the final product).

- Measure the process outputs (how much final products you can produce with given inputs)

- Measure the time it takes you to complete the process

- Measure the defect rate. What % of output comes out as faulty?

If after BPR, you managed to produce more outputs or cut the production time, given the same (or less) amount of input and defect rate, that means that the initiative was successful.

Step 5: Implement the New Process

Once you have prepared your company for a change, defined all the project requirements, and KPIs, you can proceed to the most important part of BPR – implementation.

The key to successful implementation is in making small changes while implementing changes and making sure that things are going according to the plan.

However, in real life, things are usually not that simple.

For instance, if you are trying to implement new machinery, you cannot just install 1/10th of the equipment and measure the change.

The key in situations like this one is to implement the big step in the process and constantly monitor its performance.

Additionally, you want to check how the changes affect other processes within your value chain.

For example, if you use workflow software to handle customer inquiries instead of having many customer representatives, the average response time will lower (Your key KPI).

Moreover, the email automation and automatic distribution of invoices that come with new workflow software cut down the time it takes to acknowledge and ship the orders.

Effectively, this BPR initiative aimed at 1 process (customer service) created more value for your company by improving another process down the value chain.

Therefore, you should look at the BPR implementation as the top-down process affecting the entire organization, rather than being focused on a specific process in isolation.

BPR implementation can be illustrated in another example. Let’s say that you wanted to implement an automated training platform in your organization to reduce the time it takes to distribute training materials.

When done manually, the employee supervisor would have to first prepare the right set of materials for an employee, schedule a meeting, pass the documents, and walk the employee through each one of them. This step could take up to a day to complete.

Using the advantages of new training software and automated distribution of customized training documents, this step would only take you 20 minutes.

By measuring the distribution time, it becomes clear that this BPR step is efficient, so you can proceed to redesign the next step in your training program (onboarding).

Step 6: Compare KPI performance

Once you’ve implemented the process, you need to constantly benchmark its results to your KPIs.

If the new process is underperforming, you can do a top-down analysis of the entire system and identify potential inefficiencies or bottlenecks.

Keep in mind that your business functions as a single organism, so it’s important to check if the process you improved doesn’t have a negative change to some other process.

Therefore, you have to see how the reengineered process affects your other processes within the value chain. This means that you have to analyze the effects of a new process on the entire organization

2 Real-Life Examples of Business Process Reengineering

Now that we’ve covered the BPR basics, let’s talk about examples.

We’re going to analyze 2 successful business process reengineering initiatives: one by Honeywell and another by Ford…

Business Process Reengineering Example: Honeywell

In 1990, Honeywell decided to revamp the construction process at one of their industrial automation and control business units in Phoenix, Arizona.

The goal was to reduce the number of defects and reduce the cycle time (those were the key KPIs).

Honeywell started their BPR by carefully analyzing what was wrong with the production process in the first place.

Two key issues were identified:

- When teams failed, the cause could almost always be attributed to the lack of authority to make decisions.

- Teams were focused only on quality control in their department and did not cooperate with other departments to ensure total quality control

Once Honeywell understood that lack of teamwork and authority were the key problems causing the high rejection ratio of produced parts, they decided to completely redesign their production process.

They started planning the change by mapping out the processes within the organization and communicating current inefficiencies to their employees.

Afterward, the top management developed a thorough training program and stopped the production process entirely for some time. Additionally, every employee had to complete an extensive 6-hour training session to understand how the new production system works.

Also, to achieve a higher sense of responsibility and encourage teamwork, Honeywell implemented salary-based compensation based on performance levels instead of fixed wages.

The new pay system rewarded workers based on the overall production output (and quality) in the Arizona plant.

Moreover, instead of assigning workers to specific areas on the floor, teams of multi-skilled employees were charged with building entire products or modules from start to finish.

These two advancements reinforced teamwork and total quality management throughout the organization.

Another important change was the introduction of the TotalPlant factory program. This program removed all the machinery and different software programs that were previously used separately on different steps in the process.

Instead, Honeywell created integrated hardware, software, and services that ensured top-down communication and collaboration between all the steps in the process.

This ensured constant quality monitoring and further reinforced teamwork and deregulated decision-making within the organization.

As a result of business process reengineering (that took slightly over 3 years to implement), Honeywell was able to reduce:

- Defect rates by 70 percent

- Customer rejects by 57 percent

- Cycle time on parts by 72 percent

- Inventory investment by 46 percent

- Customer lead times by over 70 percent

Before the business process reengineering at Honeywell, teams used to view the process of product creation solely from the perspective of their tasks. This made them miss out on the design defects of the final product as a whole.

And even if they did spot some potential defects in product design, it was almost impossible to suggest changes due to high decision-making bureaucracy

Moreover, they were rewarded based on the number of hours worked, as opposed to being paid for performance, which did not encourage either teamwork or quality control.

Using business process reengineering concepts, Honeywell was able to identify inefficient processes, assign relevant KPIs, design a successful implementation plan, and revamp their operations completely to increase production efficiency.

The following 5 lessons can be learned from Honeywell BPR example:

- A carefully designed plan separates successful performers from failed projects.

- Top management should make change management a top priority and communicate the change vision across the organization.

- Employee buy-in can be stimulated by more efficient reward programs

- A successful BPR strategy takes a lot of time, patience and resources

- Systematic methodologies and process mapping help people to better adapt to change.

Business Process Reengineering Example: Ford

In the 1980s, many expanding American companies were looking for ways to cut down on administrative and overhead costs. Ford was no different.

When ford started looking for things that could be improved in the organization, they have spotted that their account payable department currently employs 500 people.

When Ford looked at their smaller competitor, Mazda, they were astounded to find out that their accounts payable department consisted of 5 workers. This meant if Ford implemented a similar technology, the company could reduce the number of workers to 100.

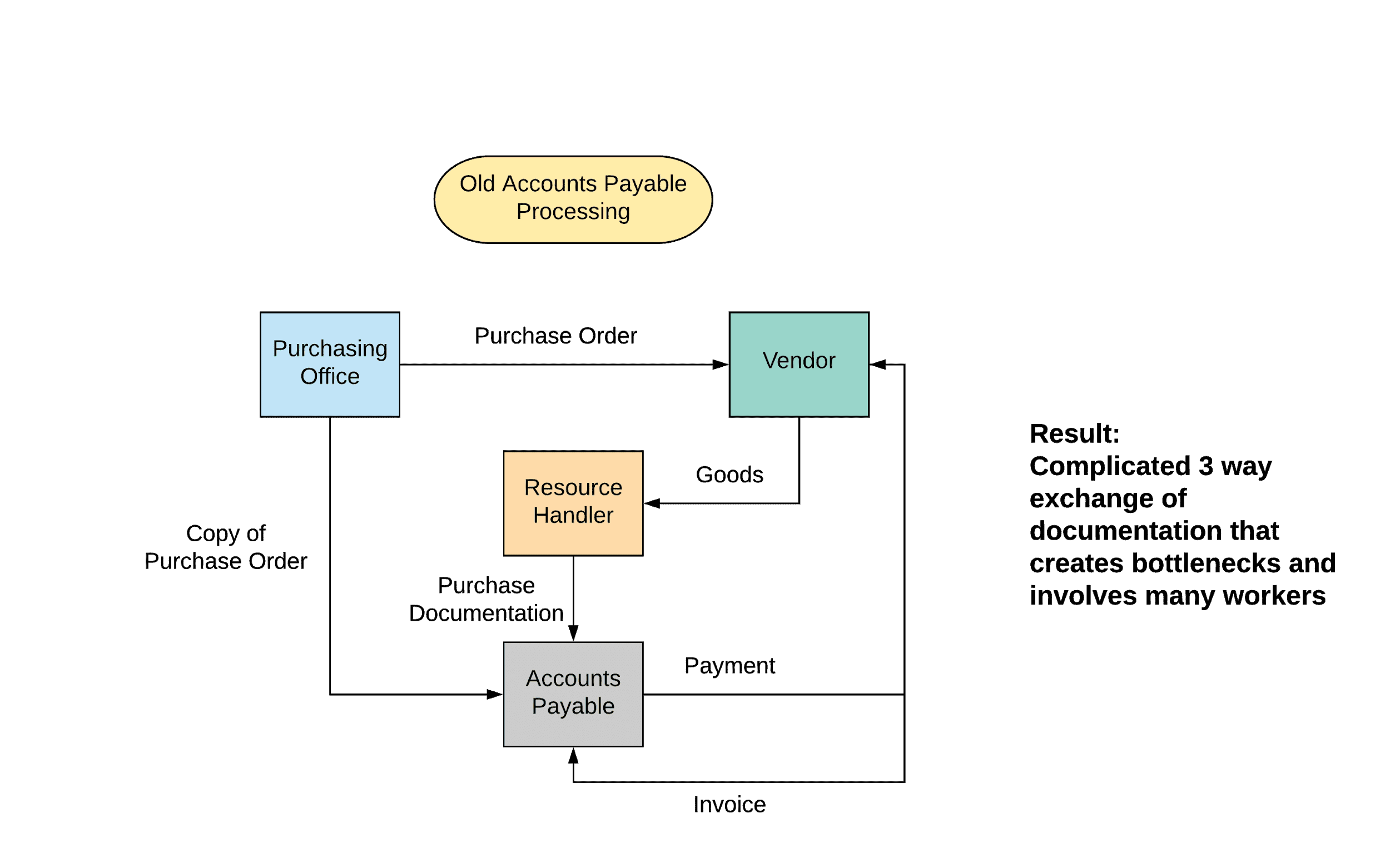

To understand, how they can make the department more efficient, Ford analyzed the old process:

- Once the purchasing department writes a purchase order, they have to send a copy to accounts payable manually.

- Then, the person responsible for resource allocation would receive the goods, and send a copy of the related document to accounts payable.

- Afterward, the vendor would send a receipt for the goods to accounts payable.

The old process involved 3 distinct human interactions that required approvals, which had to be obtained manually. This created bottlenecks:

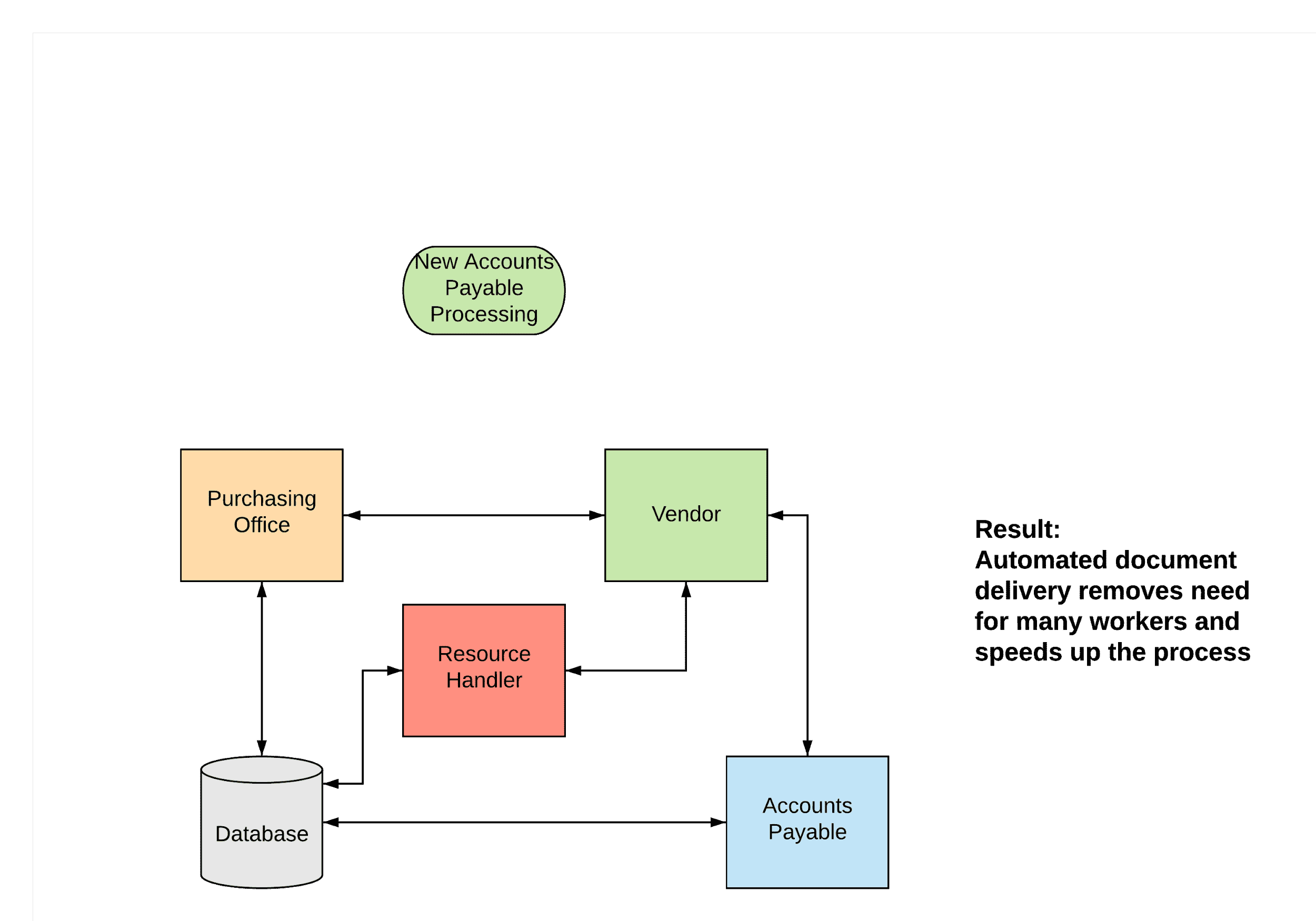

Ford decided to implement the innovative (at that tie) strategy of using computer software and databases to store and transfer information automatically.

When done digitally, accounts payable processing becomes quicker and reduces the number of workers involved. The redesigned process worked like this:

- Purchasing office issues an order and inputs it into an online database.

- Resource manager receives the goods and checks if the order matches the information in the database

- If there’s a match, material control accepts the order on the computer.

The automation of document processing saves a lot of time:

BPR as Part of Process Management – What You Need to Know

There are a ton of different methodologies revolving around process management – BPM, BPI, BPR, etc. making it extremely hard to understand what’s what.

Here’s a simple rundown:

BPI makes small adjustments to an existing process to improve efficiency.

BPR completely redefines how your processes work. It is a one-off initiative aimed at recreating your process and making it work significantly better through innovation.

You can easily understand the difference between BPI and BPR using an example.

Implementing BPI into your organization is like buying a more powerful processor for your computer: It works similarly that your old processor, but it squeezes out more performance by using more powerful components.

On the other hand, BPR is an act of completely revamping the technology used in processor manufacturing and creating a quantum computer, which is capable of calculating things 100 million times faster.

A more traditional example would be improving your horseshoes to make your stallion run faster (BPI) versus building a car (BPR).

BPR and BPI are both parts of Business Process Management (BPM).

Business Process Management (BPM) is a methodology of process improvement. I.e. “doing BPM” means that your business, on an ongoing basis, conducts process improvement and reengineering.

Recap

Phew…That is a lot of information to digest. To make it easier for you, here’s a quick summary of the findings:

- Business Process Reengineering is an act of redesigning company processes to achieve higher efficiency, lower costs, and/or higher quality

- BPR is a part of the business process management framework

- It is your role as a leader to communicate the benefits of BPR to your organization as a whole, as well as personally to your workers BEFORE implementing it

- It requires innovation, careful planning and constant monitoring of relevant KPIs before, during and after implementation

- BPR can take years to complete, requires a well-suited team and buy-in from the entire organization

Business process reengineering is complex, but it has the potential of completely transforming your organization for the better.

A lot of companies, such as Honeywell and Ford benefited from the innovation and efficiency brought by BPR. Others, like Kodak, failed to do it on time. We hope you will join the first group.

If this article helped you understand how you can channel the hidden powers of your company through BPR, make sure to follow our blog for more high-quality content!