Ask yourself: are your processes performing as well as they could be?

Are you REALLY getting the best out of your business?

More often than not, the answer is “No.”

There’s always a potential for improvement, whether it’s incremental or breakthrough.

Which is why it’s important to constantly carry out business process improvement for your organization.

And we’re about to teach you how!

In this guide, we’re going to cover:

- What’s business process improvement (w/ examples)

- 5 steps of every business process improvement (BPI) initiative

- 3+ essential business process improvement techniques

- 3+ practical ideas on how to improve your processes

- How BPI fits into the world of process management, and what are the other essential terms you need to know

So, let’s get right to it!

What’s Business Process Improvement (BPI)?

Business process improvement, or BPI, in short, is a methodology for constantly analyzing and improving your business processes.

Most BPI initiatives involve:

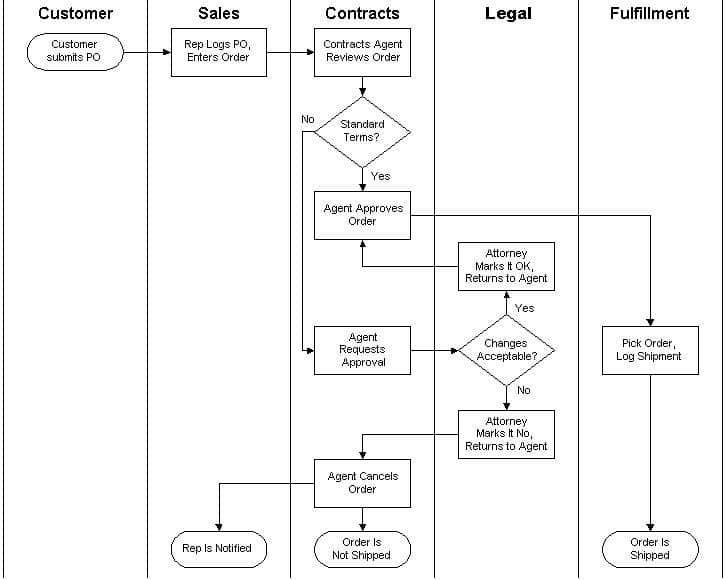

- Process Mapping – you map the process in a flowchart to have a visual representation of your process.

- Process Analysis – you analyze the process and find where exactly it is underperforming and what is causing bottlenecks.

- Process Improvement – you come up with possible improvements and you implement them where needed.

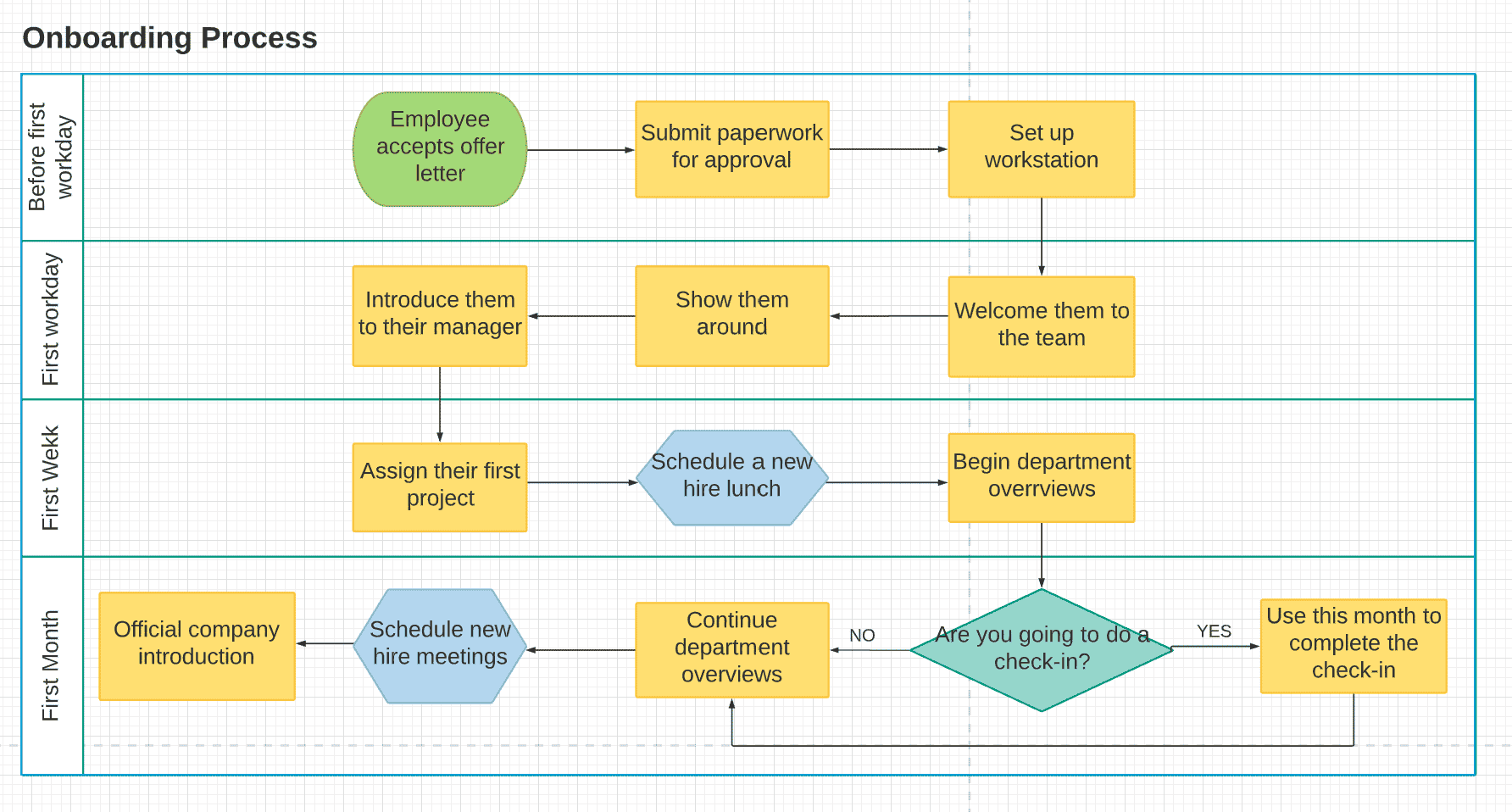

Now to put this into practice, let’s see how BPI works in a real business case like the employee onboarding process.

The onboarding process is often overlooked by management. In fact, 36% of the companies don’t have a specific structure for their onboarding which negatively impacts the new hire’s productivity, satisfaction, and engagement.

An unstructured onboarding process is bad not only for the new hire but also for the company. It leads to more inefficiencies and higher employee turnover.

According to the well-known recruiter Jörgen Sundberg, a bad onboarding process can cost you up to $240,000.

The process is partially assigned to the HR department and partially to the management team, so the lack of a clearly-defined structure makes room for miscommunication and mistakes along the way.

Also, there are a bunch of small tasks, like forwarding the employment documents and approving them for example, which can easily be automated.

This way, the focus can shift entirely toward the new hire’s adaptation and learning process.

Generally, you can improve the employee onboarding process in a few ways:

- Map out the process. Seeing it visually might give you some insights on what goes wrong and when.

- Analyze the process in-depth to understand the cause and effect relationship between the different stages. Here you might stumble upon the underlying problems behind the inefficiencies and redundant steps along the way.

- Structure your onboarding. Create a standardized process for employee onboarding, and adopt it company-wide. This can, potentially, increase the new employee’s productivity by 50%.

- Use BPM software to automate your employee onboarding workflow. The software will reduce the time and effort spent on the onboarding process and it will track the progress of all key steps for you. We’re going to explain more about this later.

Business Process Improvement (BPI) Steps

Step #1 – Process Mapping

To understand where and how you can improve your business process, first, you have to map it out.

Mapping allows you to visualize your process and get a top-down view of it. This makes it easier to analyze the process as a whole.

To map the process you just need to transform it into a process flowchart (think, a flowchart that covers every step of your process):

There are several ways to do the actual visualization.

You can do something basic like draw it with a pen and paper.

This is the easiest way to create a map, but it’s not all that useful either.

You can’t share a hand-drawn map with others, nor can you store it online.

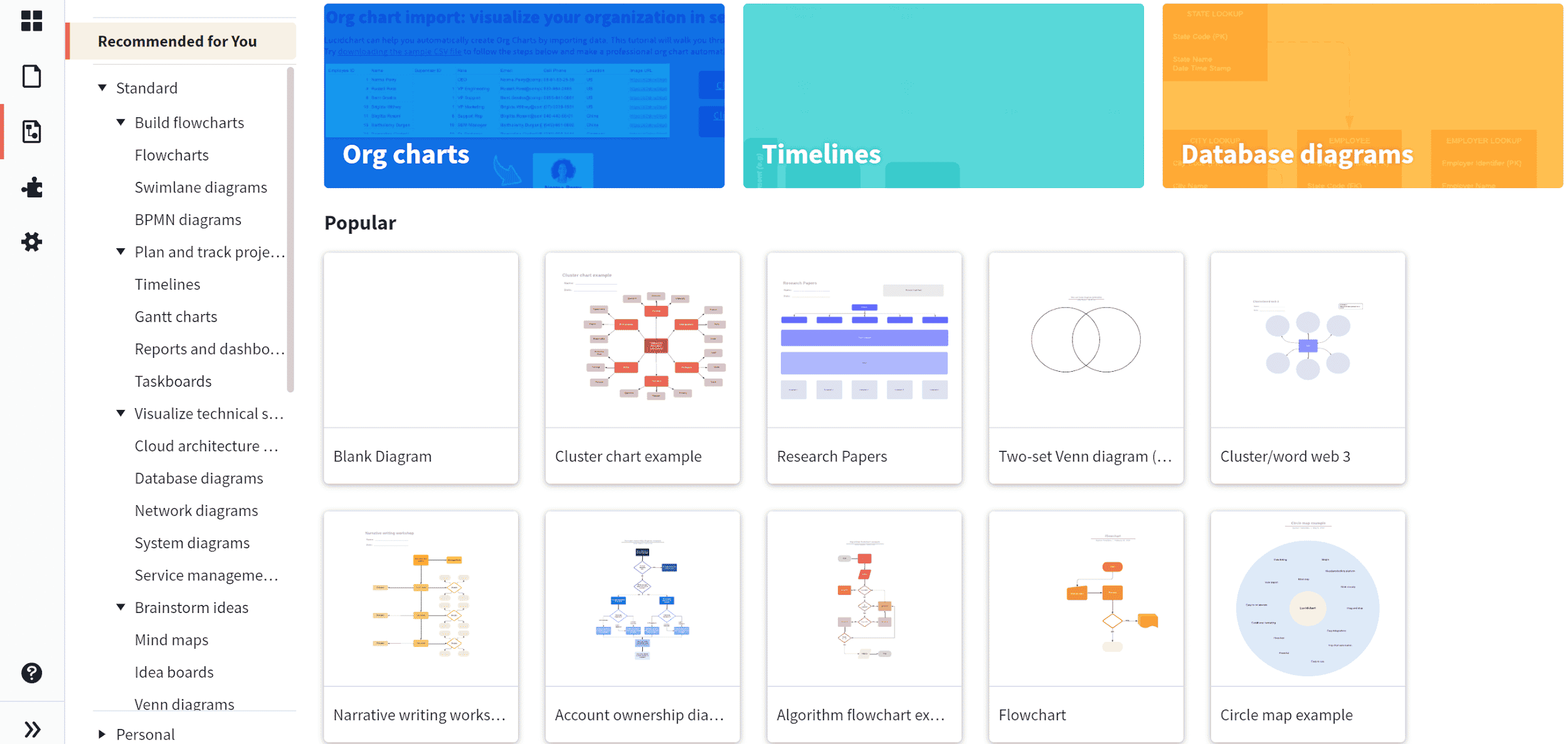

A more practical way to create your process maps is through an online graphing tool like LucidChart.

This is a relatively easy and quick way of mapping your processes. All you have to do is pick a template and customize it.

Once you’re done with your flowchart you can either download it or put it in a Google Doc folder where you can easily share it with your employees or any other relevant party.

And you don’t have to worry about losing the drafts since all of them are stored on the platform in case you want to make some further changes.

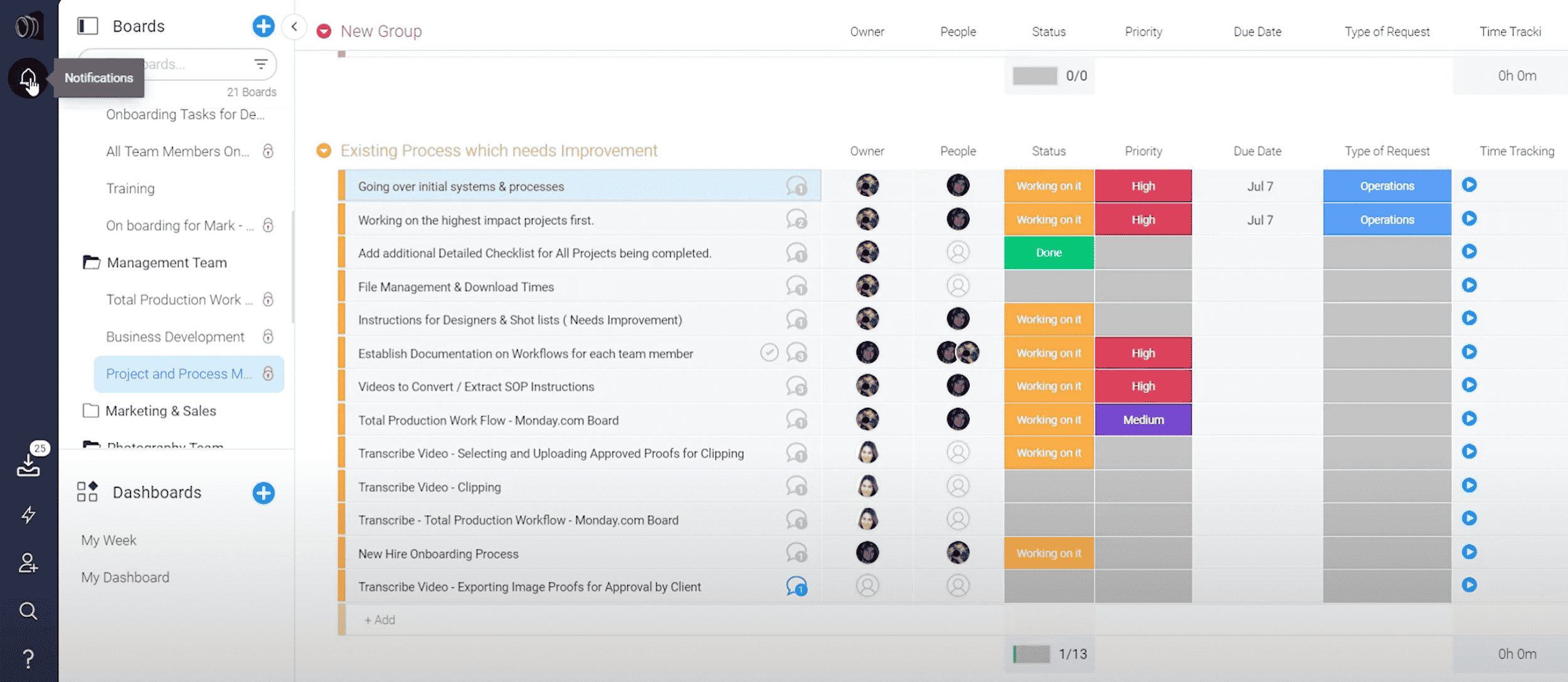

Finally, you can use dedicated business process management software like Monday.com to map your processes.

The software will assist you in creating a digitized version of your processes rather than forcing you to draw them.

The software will also help execute the process. Meaning, once someone starts a process, the software will delegate tasks to the right people at the right time & ensure that the process is executed right / on time.

And on top of that, Monday.com will also allow you to track the performance of your processes.

For example, you can get a notification whenever someone is close to missing a deadline, or a process is underperforming.

Step #2 – Process Analysis

Once you have your process mapped out, you can start analyzing it to see:

- Are any of the steps taking too much time?

- If yes, then what’s causing the delays?

- Which are the most essential steps in this process? Can they be improved?

- Are there any steps that are too costly? If yes, then, why and how can you cut on costs?

After this analysis, you will be able to pinpoint where exactly your process breaks down.

Step #3 – Process Redesign

Now that you know what the issues are and where exactly they occur in the process, you can start working on resolving them.

Of course, there is no out-of-the-box solution you can apply here. The improvements you’re going to make really vary depending on what your business is all about.

To complete this step effectively, do the following:

- Work with the people who are directly involved in the specific process. They are the ones who know it inside out, making them a valuable source of information on what can be done better (and how).

- Think about the long-term effect of your solution. You’re not after a quick fix but a solution that will show efficient results in the future.

- Always run your potential solution through risk analysis. You need to understand what are the consequences of the changes you’re about to make. After all, you don’t want to fix 1 issue but trigger 5 other problems along the way.

- Come up with KPIs that will allow you to compare the results before and after the changes you made. This will help you validate the effectiveness of your solution.

Step #4 – Process Design Implementation

After you came up with the new design, think about how you’re going to approach the implementation.

For example, you can:

- Apply the changes on a small scale to see what’s their impact before you decide to implement them across the entire organization. This will allow you to spend a minimal amount of resources on testing your improvement.

- Make sure you have all the resources and time you need to implement the necessary changes.

- Get feedback from the employees who are impacted by the change. This will help you understand if the change actually has a good effect on the process or if there is more room for improvement.

- If the new design brings a positive change, you’re ready to implement it on a larger scale.

Step #5 – Monitoring & Benchmarking

After you’ve completed all of the above steps you probably reached the desired result. But BPI is a continuous process. That’s why you want to keep monitoring your processes even after all changes are implemented successfully. Along the way, you will find more opportunities to improve your processes even further.

However, you should always think about the long-term process improvement rather than the short-term results.

In a lot of cases, what might seem to be better in the short-term, might actually be bad for the company in the long-term.

E.g. you might find out that while your manufacturing process DOES lead to more output, it also comes with a significantly higher defect rate in the long-term, which pretty much brings you back to square one.

Business Process Improvement (BPI) Techniques

Other than the standard improvement process we described above, there are a lot of other process improvement techniques you can use, including…

Define, Measure, Analyze, Improve, Control (DMAIC)

DMAIC is a technique used to minimize errors. It stands for define, measure, analyze, improve, and control.

Here’s what each of those steps means…

- Define – You determine the problem and its impact on your company. Then you define your goals and the resources you’ll need to resolve it.

- Measure – You measure the performance of the process and understand which steps are underperforming. This is where you will find the root cause of the problem.

- Analyze – You analyze the problematic steps and specify their cause and effect relationship with the overall process performance.

- Improve – Come up with possible solutions to the issue. Test them out and see if any of them bring a positive change to the process performance.

- Control – Once you find a good improvement solution, you want the positive changes to stick around. You can create a control system that monitors the process’s performance so you can understand when and where you can improve more.

5 Whys

The concept of the 5 Whys is to keep asking “Why?” until you reach the root cause of your problem.

How you go about it is, you gather the employees connected to the respective issue, you define the problem you’re facing, and you start asking your 5 Whys.

By the end, you will understand how the chain of errors led to the bigger problem which you now have to deal with.

Let’s say, for example, that your business unit will not be able to meet the yearly sales objective. You will gather your sales team, explain the purpose of the meeting, and start searching for the root problem.

- Why didn’t we reach our objective to reach 20% more sales? Because we can’t produce more.

- Why? Because we don’t have enough qualified workers onsite.

- Why? Because we reached our limit on the training budget.

- Why? Because the top management cut our budget.

- Why? Because they decided to allocate more money to R&D this year.

Now you’ve reached the root of the problem and you can come up with an effective solution.

In this specific example, you might want to inform the top management of the issue and see how they can help you to meet your Strategic Business Unit’s objective.

PDCA

The PDCA method stands for Plan-Do-Check-Act. It is a change management model used to continuously improve your processes and resolve any recurring problems.

You can test out different solutions to your problem on a small scale and gain a better understanding of how a specific change impacts your entire process.

Then if appropriate, apply the changes company-wide.

The steps to this method are:

- Plan – Identify your problem and map out how you can change the process. You can develop hypotheses on what are the underlying issues and test them out.

- Do – Develop a solution and test it on a smaller scale. Then measure your results from before and after the implemented changes.

- Check – Analyze the effectiveness of the possible solution and confirm whether it actually resolved your problems or not. If yes, was it smooth enough or does it need to be improved more? Evaluate your results with attention to such details.

- Act – If your hypothetical solution performed well, then you can go on and implement it. If not, you have to go back to the first step of the PDCA cycle, make all necessary adjustments, and test again.

3 Simple Process Improvement Ideas

Other than going through the typical steps for process improvement, you can also try these 3 process improvement ideas…

- Use BPM Software. Just by adopting BPM software, you can automate menial tasks and minimize human error. The software also gives you a top-down view of your processes so you can easily spot underperforming ones. At the same time, your management team will get automated notifications if any given process is close to missing a deadline (w/ a run-down on why).

- Automate Simple Tasks. You can use Zapier to automate some of your tasks like email responses, schedule meetings, and build workflows for some repetitive tasks. This will allow you to allocate more time and resources to other more crucial tasks.

- Automate Your Social Media. You can use Publer to automate your social media processes. If social media plays a big role in your company, automating your posting schedule is a good idea.

Process Management and You – What You Need to Know

Business Process Management (BPM) – BPM is a methodology of continuously tracking, analyzing, redesigning, and improving your business processes.

It helps you to always be on track with how your processes perform and tracks their progress.

Usually, BPM involves doing business process improvement on a regular basis.

Business Process Automation (BPA) – BPA is the act of automating menial tasks and process flow automation. Usually, automation happens with the help of BPM software.

Business Process Management Software (BPMS) – BPMS allows you to build digital versions of all your processes and it enables you to have better control over the processes, see the bigger picture, and automate certain tasks.

Conclusion

To recap, let’s see what we’ve covered so far…

- BPI is the act of improving your business processes.

- BPI is carried out in 5 main steps: mapping, analysis, redesign, implementation, and monitoring.

- You can also use other BPI techniques like DMAIC, the 5 Whys, and PDCA.

- Some other ideas on how to put BPI in action are: BMPS, task automation, and social media automation software.

I hope you found the article useful and already have some ideas on how to implement BPI for your business.

For industry-leading process management content, make sure to follow our blog!